Contact Us

Contact Us

0086-19878953251

0086-19878953251

| Minimum Order Quantity: | 1 |

| Packaging Details: | Freight packaging |

| Delivery Time: | 4 months |

| Payment Terms: | 30% Advance charge 65% Payment for shipment 5% Delivery payment |

| Supply Ability: | Annual production of 20 sets |

Ensuring the uniformity of product quality relies heavily on the ability to swiftly and consistently inspect internal structures and materials. Rapid and reliable inspections are the cornerstone of maintaining product quality standards.

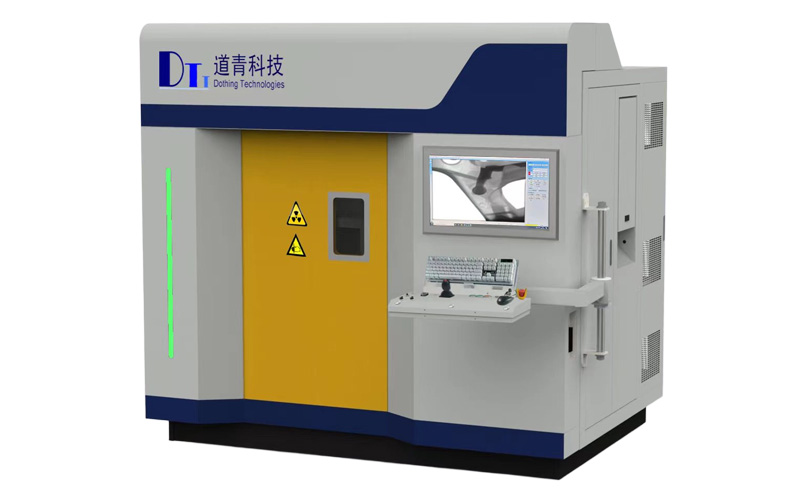

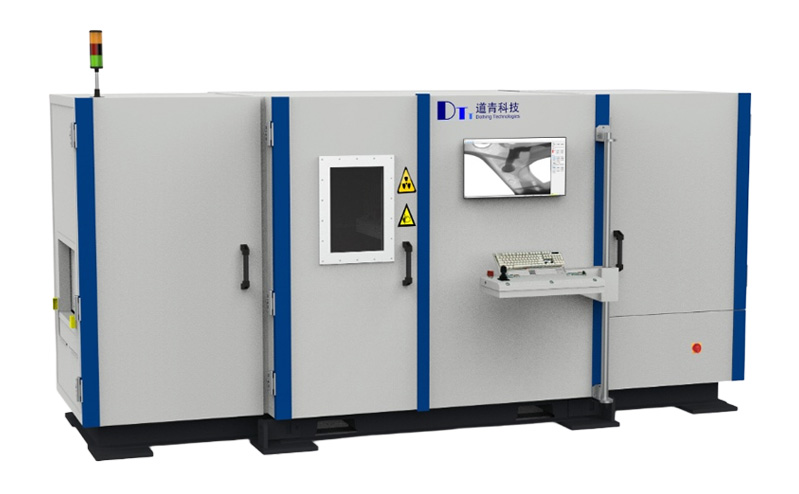

Daoqing's DU310 solution represents the pinnacle of efficiency and reliability in this regard. Equipped with state-of-the-art digital flat panel imagers and Daoqing's cutting-edge HDI technology, it offers unparalleled performance in both sampling and comprehensive 100% inspections. Whether it's steel, aluminum, ceramics, composite materials, or rubber, the DU310 is adept at delivering high-quality inspection results across various materials.

The DU310's independent C-arm design is a testament to Daoqing's commitment to versatility and space optimization. By maximizing flexibility while minimizing footprint, it ensures seamless integration into diverse operational environments.

Thanks to its advanced software system, the DU310 delivers exceptional image quality, with Daoqing's HDI technology swiftly identifying even the minutest internal details of the product. Designed with user experience in mind, the system boasts intuitive controls, reducing inspection time and adhering to stringent industry standards such as ASTM E2737-10 and DICONDE.

In essence, the DU310 isn't just a tool for inspection; it's a cornerstone of quality assurance, offering longevity, reliability, and uncompromising performance in every inspection cycle.

| Subframe | Steering knuckle |

| Automotive components | Castings (aluminum or steel) |

| Aerospace components |

The detection area of the large-sized disc provides excellent versatility, making it suitable for various applications.

The electromechanical system is mature and reliable, capable of withstanding harsh environments.

The rapid lift door enables quick and convenient loading and unloading of items.

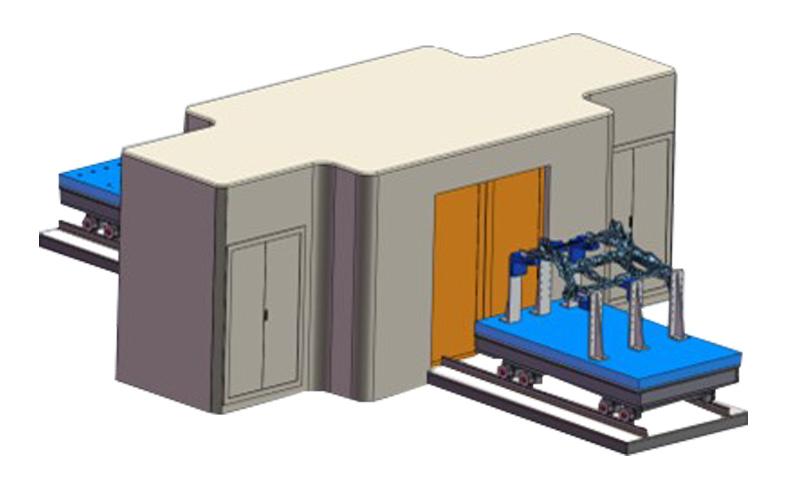

Simultaneous loading, unloading, and detection processes ensure efficient testing operations.

The C-arm ensures optimal image quality for accurate inspections.

Different speed and acceleration settings are optimized for each axis to enhance performance.

All six axes are controlled by CNC, facilitating precise and customizable motion sequences.

Dynamic real-time imaging and static imaging functions are integrated for comprehensive inspection capabilities.

The high-quality image results from the advanced digital flat-panel imaging device (FP) and our proprietary HDI technology.

HDI technology ensures instant (0.3-1.3s) acquisition of high-definition images.

HDI is insensitive to X-ray dosage and thickness parameters, ensuring consistent performance.

HDI allows for accurate assessment of defects' depth in castings.

The system can be deployed in any workplace without the need for additional radiation protection measures.

Exceeding the radiation protection safety standards outlined in GB18871-2002.

We offer localized chip-level repair services for maintenance needs.

| Technical Parameters | DU310 | DU310X | ||||||

| Workpiece Dimensions, Weight | 1,200 × 680 × 400H mm, 30kg | 1,500 × 850 × 550H mm, 30kg | ||||||

| Loading Platform Diameter | Loading Platform Diameter | 1,620 × 970 mm | ||||||

| Stroke/Speed | 6-Axis | 6-Axis | ||||||

| Longitudinal Tx axis | 1200mm,Speed 4-15 m/min | 1500mm, Speed4-15 m/min | ||||||

| Transverse Ty axis | 500mm, Speed4-15 m/min | 800mm, Speed4-15 m/min | ||||||

| Vertical Tz axis | 600mm, Speed4-15 m/min | 800mm, Speed4-15 m/min | ||||||

| Rotational Rx | ±75°, Rotation Speed3-8 R/min | ±75°,, Rotation Speed3-8 R/min | ||||||

| Tilted Ry | ±80°, Rotation Speed3-7°/s | ±80°, Rotation Speed3-7°/s | ||||||

| Focal length (adjustable) | 650mm – 950mm | 900mm – 1,250mm | ||||||

| Imaging Detector 1 | ||||||||

| Input Window | 204mm×204mm | |||||||

| Pixel | 1024×1024 with a spacing of 200μm | |||||||

| Gray Scale Level | 65,536(16bit) | |||||||

| Frame Rate | 25fps、;。78 | |||||||

| Imaging Detector 2 | ||||||||

| Input Window | 430mm×430mm | |||||||

| Pixel | 3072×3072 with a spacing of 139μm | |||||||

| Gray Scale Level | 65,536(16bit) | |||||||

| Frame Rate | 4-15fps | |||||||

| System Control Console | ||||||||

| Power | 3P×380Vac,50Hz,10-20kVA | |||||||

| Gas source | 0.4-0.6MPa | |||||||

| Lead Room Dimensions(W,H,D) | 2,150× 2,700× 1,800mm | 2,200× 2,750× 1,850mm | 2,400× 2,750× 1,950mm | 2,800× 2,800× 2,500mm | 2,450× 3,000× 2,050mm | 2,550× 3,350× 2,100mm | 2,750× 3,500× 2,200mm | 3,400× 3,550× 2,750mm |

| X-ray source | 160kV | 225kV | 320kV | 450kV | 160kV | 225kV | 320kV | 450kV |

| Focus (EN12543) | 1.0/0.4 mm, power 1800/800 W (1500/700W@450kV) | |||||||

| Optional accessories | AI defect automatic identification function, robot loading and unloading device, customizable. | |||||||

Automotive Parts Digital Imaging Inspection System

Industrial X-ray Intelligent Testing Equipment

Automotive Parts Online Inspection System

Multi-degree-of-freedom Intelligent Robotic X-ray Inspection Equipment for Complex Castings

| |

| |

| |

|

if you cannot find answer to your question our FAQ, you can alwas contact us. web will answer you shortly!