Contact Us

Contact Us

0086-19878953251

0086-19878953251

| Minimum Order Quantity: | 1 |

| Packaging Details: | Freight packaging |

| Delivery Time: | 4 months |

| Payment Terms: | 30% Advance charge 65% Payment for shipment 5% Delivery payment |

| Supply Ability: | Annual production of 20 sets |

The quality of weld seams on gas cylinders is paramount for ensuring smooth operation, making it a pivotal aspect of quality control. Batch rapid testing is an essential requirement in this regard.

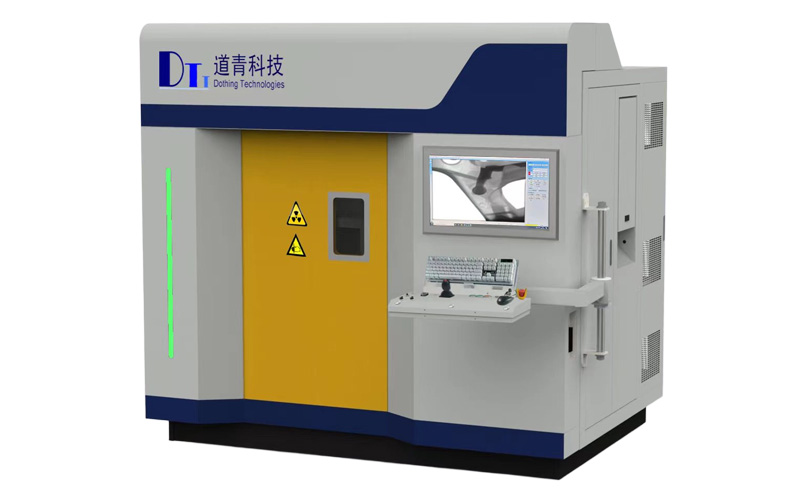

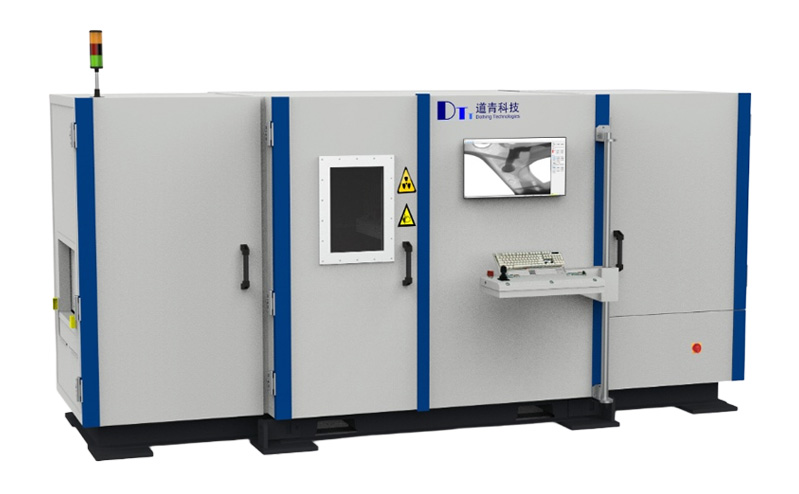

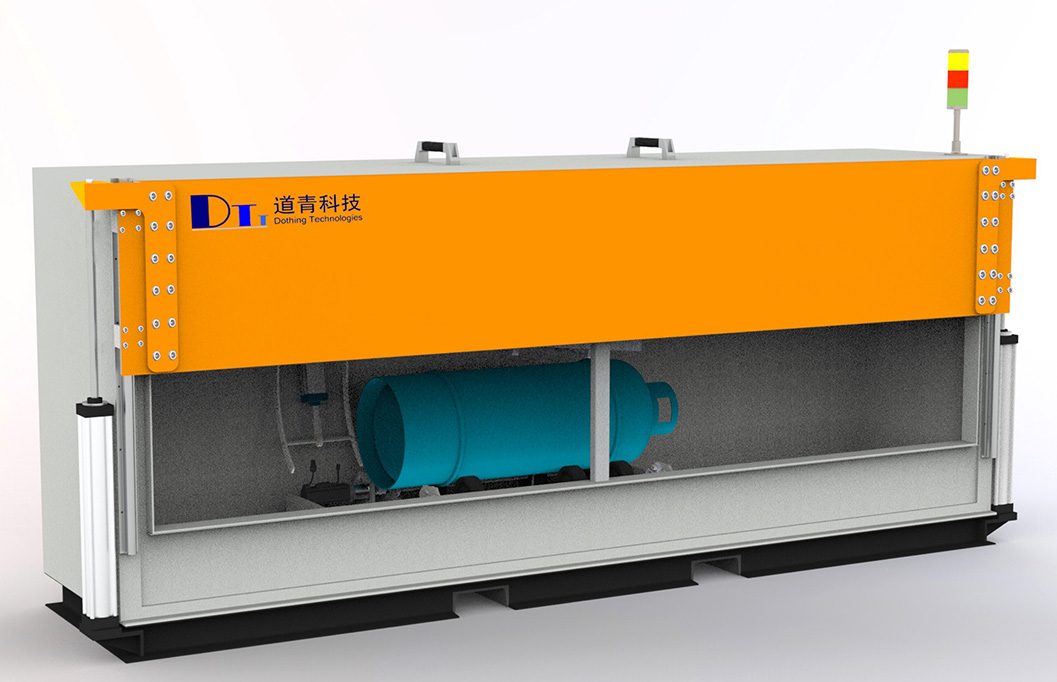

Daoqing Technology has globally delivered over two hundred sets of gas cylinder weld seam inspection systems. The fourth-generation DU201 solution has emerged as the most practical, reliable, widely applicable, and preferred low-cost solution for gas cylinder inspection. Renowned for its outstanding defect detection rate and user-friendly operation, it incorporates Daoqing Technology's High Definition Image (HDI) processing technology, delivering unmatched defect detection results. It meets the stringent standards of GB/T17925 and ASME V, ensuring high-quality inspections.

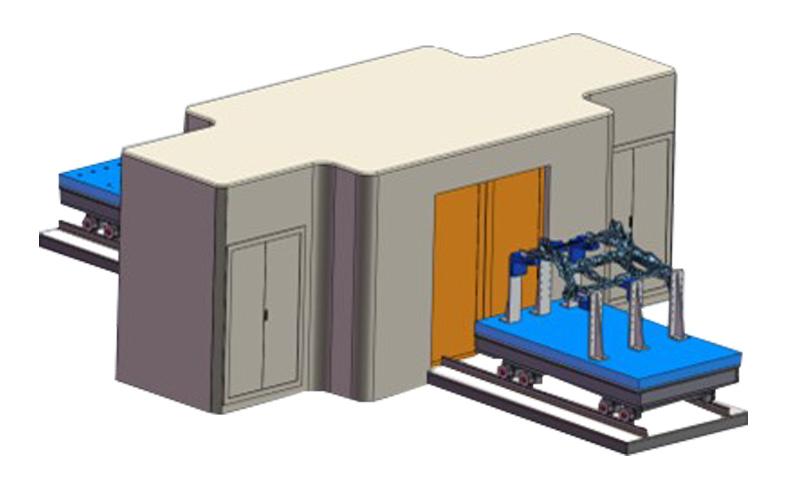

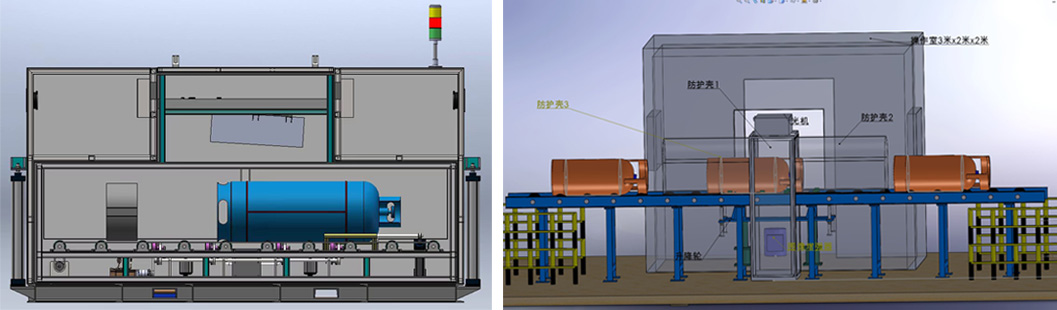

The DU201 configuration includes X-ray sources, imaging detectors, conveyors, and inspection machinery, catering to weld seam inspection of diameters ranging from Ø200mm to Ø600mm. Customized inspection systems are also available to meet specific needs.

| Liquefied Petroleum Gas Cylinder (PNG) | Liquefied Natural Gas Cylinder (LNG) |

| Welded Insulated Gas Cylinder | Low-Temperature Gas Cylinder |

| Acetylene Gas Cylinder | Ammonia Gas Cylinde |

| Other Steel Cylinders |

Unique long-life, high-reliability control technology.

Innovative long-lasting and highly reliable control technology. Automated encoding and preservation of images.

Effortless one-touch synchronization of imaging and mechanical operations.

Automatic cessation of imaging and mechanical processes.

Exceptional image quality, courtesy of Daoqing Technology's advanced HDI technology.

The original images remain unchanged.

Daoqing's exclusive dynamic image floating window display function.

Simultaneous display of composite images on the same screen.

Automated generation of detection reports, compatible with Excel format.

Localized chip-level maintenance service.

| DU201 | ||||||

| 160kV | 200kV | |||||

| Gas Cylinder | PNG、Acetylene Gas Cylinder | PNG、LNG、Acetylene Gas Cylinder、Ammonia Gas Cylinder | ||||

| Maximum single wall thickness | ≤4.5 mm | ≤7 mm | ||||

| Diameter Ø | Ø180mm- Ø400mm | Ø180mm- Ø600mm | ||||

| Imaging Mode | Double-walled single image | |||||

| Rotational Speed | 1-12 rpm | |||||

| Image Resolution | ≥3.9Lp/mm | |||||

| Sensitivity | Satisfies GB/T17925-2011 and NB/T47013.11 | |||||

| Imaging Detector | Digital Flat Panel | |||||

| Input Window | 130mm×130mm | |||||

| Pixel | 1024×1024 with a spacing of 127μm | |||||

| Gray Scale Level | 65536(16bit) | |||||

| Frame Rate fps | 1fps-30fps (1:1) | |||||

| X-ray Source | DG160MX | DG200MX | ||||

| Tube Voltage | 75kV-160kV | 50kV-200kV | ||||

| Tube Current | 0.1-6mA | 0.1-6mA | ||||

| Focus (IEC336-1) | 0.45 | 0.45 | ||||

| X-ray Power | 480W | 500W | ||||

| System Control Console | 1,200×1,000×750mm, 65kg | |||||

| Power | P1×220Vac,50Hz,3kVA | |||||

| light gate, collimator | pneumatic light gate, 2-position pneumatic collimator | |||||

Advantages and Features | Industrial-Grade High-Resolution Enhancer Delivering the lowest equipment cost with a mature and reliable fourth-generation solution. Offers industry-leading dynamic range for exceptional image quality, combined with long-term stability and minimal maintenance requirements. Powered by the latest generation of advanced HDI imaging technology. | |||||

Model |

|

|

| |||

Applicable Cylinder Types | 5 – 50 KG | 2.5 – 50 KG | 2.5 – 15 KG | |||

Overall Dimensions (L×W×H) | 3400×950×1600 | 2100×1250×1250 | 1120×700×1200 | |||

Gas Cylinder Weld Seam Non-Destructive Testing Online (Offline) Inspection System

Steel Cylinder Weld Seam X-ray Inspection System

if you cannot find answer to your question our FAQ, you can alwas contact us. web will answer you shortly!