Contact Us

Contact Us

0086-19878953251

0086-19878953251

| Minimum Order Quantity: | 1 |

| Packaging Details: | Large machinery freight packaging / Customized wooden cases |

| Delivery Time: | 4 months |

| Payment Terms: | 30% Advance charge 65% Payment for shipment 5% Delivery payment |

| Supply Ability: | Annual production of 10 sets |

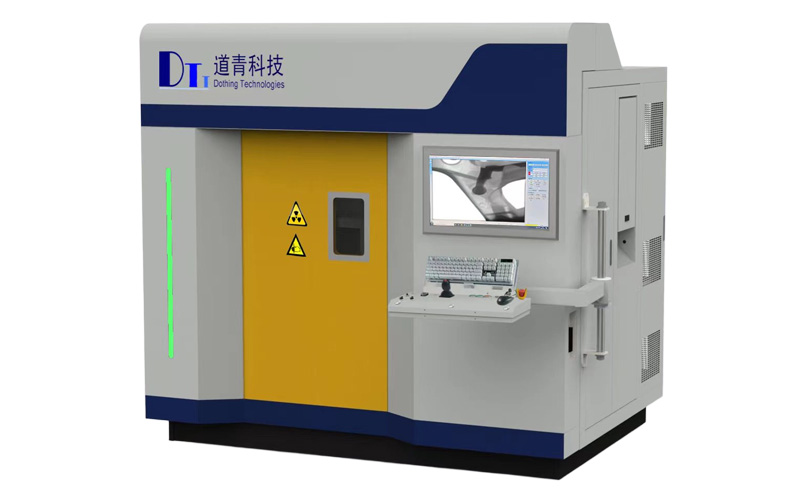

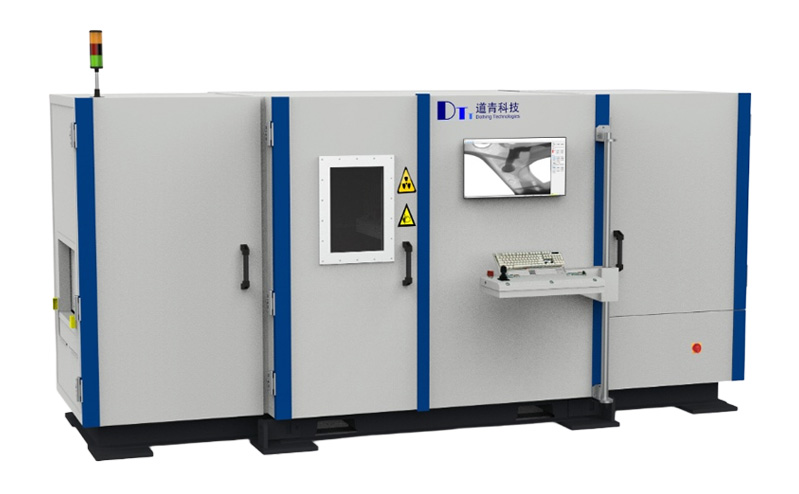

The DU312 is a state-of-the-art X-ray inspection system specifically engineered for the "Giga-casting" trend in the automotive industry. It addresses the challenges of detecting large, complex, and thin-walled parts with dimensions up to 2500×1500×700 mm.

Key Features:

High Efficiency: Equipped with dual robots and a dual-station layout, allowing for simultaneous detection and loading/unloading to maximize cycle time efficiency (approx. 110s for 20 points).

Flexible Manipulation: The 6-axis articulated robots ensure 360-degree coverage and optimal transillumination angles for complex structures.

Superior Imaging: Integrates a world-class COMET X-ray source (up to 450kV optional) and a large-format Varex flat panel detector to ensure high-resolution imaging for critical safety parts.

AI Intelligence: Powered by Dothing's XRIS software with ADR (Automatic Defect Recognition) based on AI deep learning, automatically grading defects according to ASTM E155/E2422 standards.

| Model Number | DU312 |

| Workpiece | Large-scale integrated die castings (e.g., rear floor, battery trays) |

| Workpiece Size | Max. 2500 × 1500 × 700 mm |

| Workpiece Weight | ≤ 100 kg |

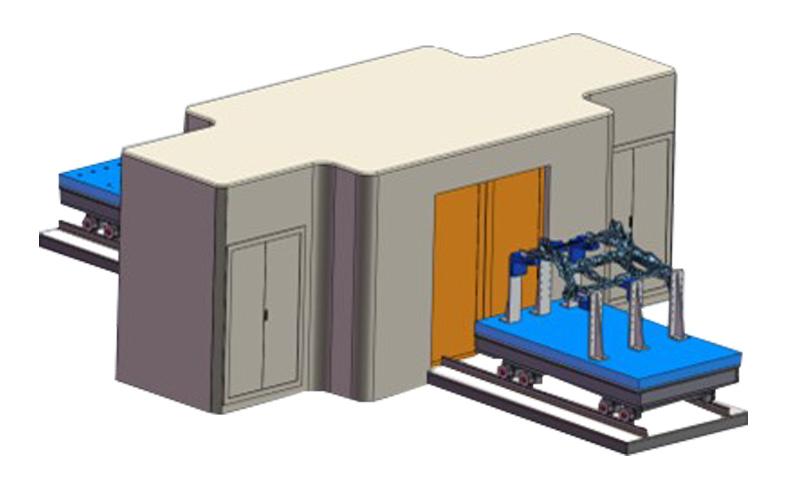

| Lead Room Dimensions (WHD) | Approx. 9500 mm × 8000 mm (Customizable based on site) |

| Lead Door | Automatic shielded door, interlocked for safety |

| Protection | Fully shielded lead room compliant with GB18871-2002; Leakage < 1µGy/h |

| Weight | Approx. 15,000 KG |

| Mechanical Transmission | 6-axis Articulated Robots (Dual robots) |

| Manipulator Type | High-precision 6-axis Articulated Robot |

| Rotating Platform IN and Out Direction | Dual-station layout for simultaneous detection and loading |

| Horizontal Rotation | 360-degree coverage via 6-axis robot manipulation |

| Focal Length (adjustable) | Flexible manipulation via Robot (FDD adjustable) |

| Manual Ejection Shaft | Automatic loading/unloading (Cycle time approx. 110s) |

| X-ray Source | DG160kV / 225kV / 320kV / 450kV (Optional) |

| Focus (EN12543) | 1.0/ 0.4mm |

| Tube Voltage | 5-450kv |

| Tube Current | 0~30mA(large focal spot ),0~15mA(small focal spot ) |

| Radiation Angle | 40°×30° |

| Power | 800/1800/4500 W |

| Image Detector | Digital Flat Panel |

| Input Window | 430 mm × 430 mm (17" × 17") |

| Pixel | 3072 × 3072(139 μm) |

| Gray Scale Level | 65,536(16bit) |

| Frame Rate | (High-speed dynamic imaging supported) |

| Dynamic Range | (High dynamic range for varying thicknesses) |

| Image Processing System | Industrial computer workstation |

| Image Processing Hardware | Industrial computer, high-speed image acquisition card |

| Image Processing Software | Dothing XRIS (with AI-based ADR function) |

| System Control Console | Integrated control station (Customizable layout) |

| Power Supply | 3-Phase AC (Voltage customized to local site, e.g., 380V/400V/480V) |

| Maximum Power | Subject to final system configuration |

Giga-casting X-ray Inspection System

Large Integrated Die Casting NDT Solution

Automotive Mega-Casting X-ray Detection Equipment

AI-Powered ADR X-ray Inspection Booth

Fully Automatic Inline X-ray System for Large Aluminum Castings

High Efficiency Dual-Station X-ray DR System

Customized X-ray Real-time Imaging System for Giga Castings

if you cannot find answer to your question our FAQ, you can alwas contact us. web will answer you shortly!