Contact Us

Contact Us

0086-19878953251

0086-19878953251

| Minimum Order Quantity: | 1 |

| Packaging Details: | Freight packaging |

| Delivery Time: | 4 months |

| Payment Terms: | 30% Advance charge 65% Payment for shipment 5% Delivery payment |

| Supply Ability: | Annual production of 20 sets |

The quality of weld seams in small-diameter pipes is crucial for ensuring the smooth operation of the entire system, making it a pivotal aspect of quality control. Batch rapid testing is an imperative requirement in this regard.

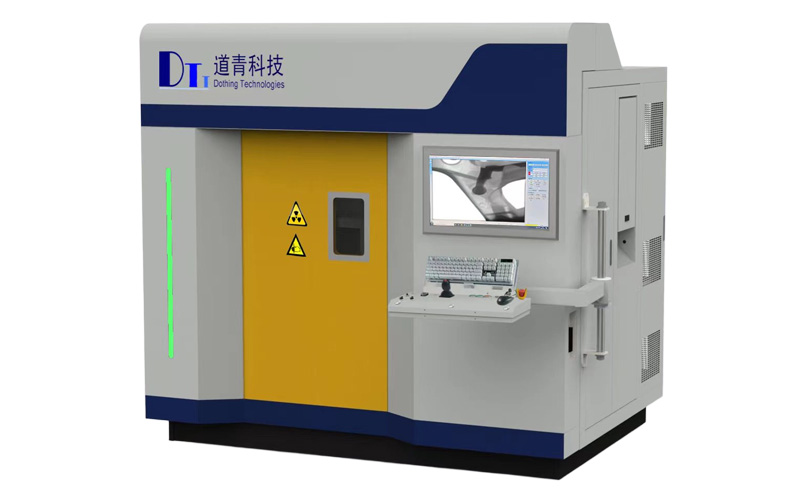

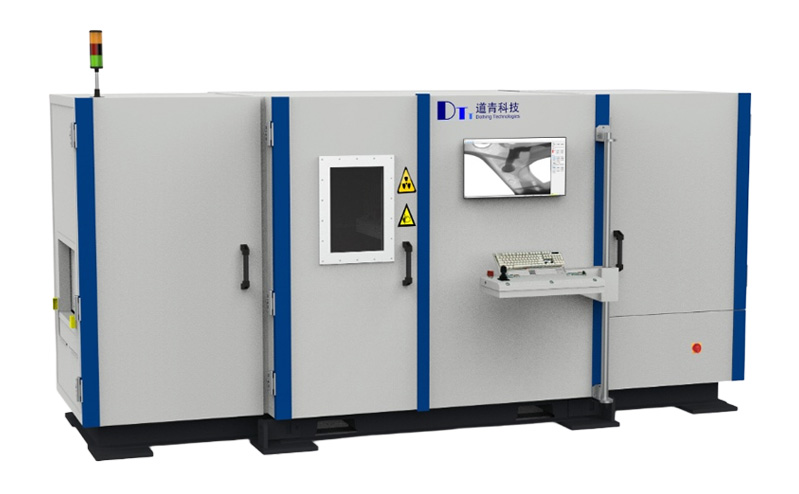

With over a decade of global supply experience in the small-diameter pipe weld seam detection industry and backed by the Suzhou X-ray Digital Imaging Technology Engineering Center, Daoqing Technology has emerged as a frontrunner in providing cutting-edge solutions for small-diameter pipe inspection systems. Our advanced DU105 solution offers rapid testing and CNC automation control processes, meticulously designed to deliver optimal detection rates with utmost simplicity in operation. Leveraging Daoqing Technology's state-of-the-art high-definition image processing technology (HDI), our system ensures unparalleled defect detection results, meeting the stringent inspection standards of JB/T4730 and ASME V for high-quality testing tasks.

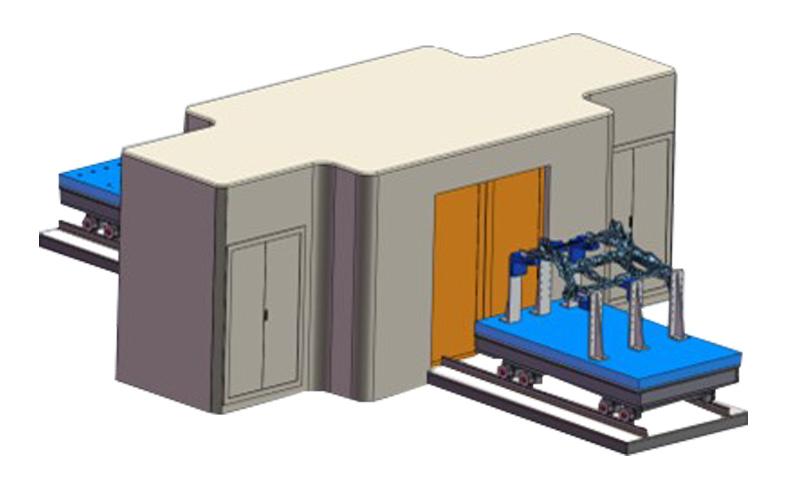

The DU105 configuration comprises an X-ray source, imaging detector, protective chamber, and conveying and rotation machinery, making it suitable for weld seam detection across various size specifications ranging from Ø25 to Ø89mm in diameter and with single-wall thicknesses of 2.0-25mm.

| Small-diameter pipes | Small-diameter pipes |

| Pattern walls | Economizers |

| Power plant boilers | Boiler accessories |

Automatic encoding and saving of images.

One-click synchronization for easy initiation of imaging and rotation processes.

Automatic cessation of imaging and rotation procedures.

High-quality image results derived from Daoqing Technology's HDI technology.

Original images are immutable.

Longevity and high reliability in design.

Daoqing's exclusive dynamic image floating window display feature enhances user experience.

Simultaneous display of stitched images on one screen for comprehensive analysis.

Automated generation of inspection reports in Excel format for convenient documentation..

Standard inclusion of essential components such as lead chamber, rotation tube mechanism, and closed-circuit monitoring ensures comprehensive functionality.

Designated shelf operation position for convenient handling and organization.

Offering localized chip-level repair services ensures prompt and efficient maintenance.

| DU105 LS | DU105 FP | DU105 II | |

| Small-caliber pipes | Ø25mm- Ø89mm | ||

| Imaging Detector | Line array | Digital Flat Panel | Image Enhance |

| Input Window | 160mm×∽ | 204mm× 204mm | Ø 145m |

| Pixel | 1884×∽ with a spacing of 83 μm | 1024×1024 with a spacing of 200 μm | 1024×1024 |

| Gray Scale Level | 4096(12bit) | 4096(12bit) | 4096(12bit) |

| Frame Rate fps, Speed ms | 1ms – 4000ms | 25fps | 30fps |

| Imaging mode | Unwrapped imaging / Elliptical imaging | Elliptical imaging | Elliptical imaging |

| Rotation speed | Line speed 0.1-2m/min | Line speed 1-5 m/min | Line speed 1-5 m/min |

| Imaging resolution | ≥4.5Lp/mm | ≥3.2Lp/mm | ≥3.2Lp/mm |

| sensitivity | Meets JB/T4730-AB standards | Meets JB/T4730-AB standards | Meets JB/T4730-AB standards |

| X-ray Source | Appropriate maximum single-wall thickness (σ_max) | Appropriate maximum single-wall thickness (σ_max) | Appropriate maximum single-wall thickness (σ_max) |

| 200kV (DG200MX) | ≤6mm | ≤8mm | ≤8mm |

| 200kV (DG200MX) | ≤6mm | ≤8mm | ≤8mm |

| 300kV (LPX300) | ≤15mm | - | - |

| 225kV (DG225) | ≤7mm | ≤10mm | ≤10mm |

| 320kV (DG320) | ≤17mm | ≤20mm | ≤20mm |

| System Control Console | 1,200×1,000mm, 65kg | ||

| Collimator | Linear scan imaging device | Two-dimensional, two-piece electric collimator | Two-dimensional, two-piece electric collimator |

| Advantages and Features | ·Optimal imaging outcomes ·Distinctive expanded image capability ·Extended operational lifespan for enhanced user experience ·Reliable and efficient design ensuring consistent performance ·Sustainable and enduring detection results ·Unmatched performance-to-value ratio Includes both large and small focal point X-ray sources ·Minimal operational expenses | ·Deliver unparalleled imaging clarity with the widest dynamic range possible ·Maximize longevity while minimizing maintenance expenses ·Harness cutting-edge imaging advancements for superior results ·Utilize a compact X-ray source with a small focal point for precise imaging | ·Utilize industrial-grade high-resolution image enhancers for superior image quality ·Take advantage of the most cost-effective equipment available ·Incorporate a compact focal point X-ray source for precise imaging |

if you cannot find answer to your question our FAQ, you can alwas contact us. web will answer you shortly!