Contact Us

Contact Us

0086-19878953251

0086-19878953251

| Minimum Order Quantity: | 1 |

| Packaging Details: | Freight packaging |

| Delivery Time: | 4 months |

| Payment Terms: | 30% Advance charge 65% Payment for shipment 5% Delivery payment |

| Supply Ability: | Annual production of 20 sets |

Weld seam internal defects are pivotal factors influencing the quality and safety of industrial components. Detecting even the minutest flaws in a timely manner is paramount for ensuring operational safety and averting potential accidents.

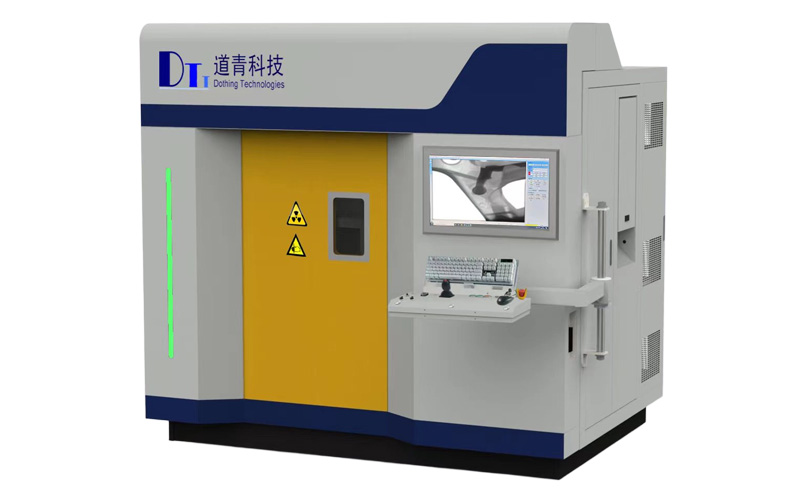

Drawing on the expertise of the Suzhou X-ray Digital Imaging Technology Engineering Center and backed by over two decades of experience in digital imaging, Daoqing Technology stands at the forefront as a leading supplier of industrial X-ray non-destructive testing systems. Our cutting-edge DU104 solution is meticulously designed to facilitate rapid and automated inspection processes, prioritizing optimal detection rates and user-friendly operation. Equipped with state-of-the-art all-digital flat panel imagers and Daoqing's advanced High-Definition Imaging (HDI) technology, our systems deliver unparalleled defect detection capabilities. They not only meet but exceed the stringent inspection standards of special equipment, such as JB/T4730 and ASME V requirements, ensuring the highest quality inspection tasks.

The DU104 configuration boasts a versatile array of components, including cranes, rollers, cantilevers, and more, making it suitable for inspecting circumferential and longitudinal weld seams across various size specifications. Offering a spectrum of X-ray source options ranging from 160kV to 600kV, along with multiple layout schemes tailored to different needs, our systems are adaptable to diverse requirements. Furthermore, they seamlessly integrate with existing conveyor machinery or Daoqing's comprehensive system, catering to specific demands with unparalleled efficacy and precision.

| Pressure Vessel Weld Seams | Boiler Cylinders |

| Pipelines | Welded Gas Cylinders |

| Vacuum Insulated Storage Tanks | Storage Tanks |

Our system seamlessly integrates fast dynamic real-time imaging with static imaging capabilities.

Providing unparalleled image quality through its cutting-edge high dynamic range digital flat panel imager (FP) and proprietary HDI technology from Daoqing Science and Technology.

Engineered for longevity and reliability, it guarantees consistent performance over extended periods of use.

HDI technology provides rapid image acquisition (0.3-1.3s) with high-definition clarity.

Maintaining insensitivity to X-ray dosage and material thickness. Additionally.

The system is equipped with standard closed-circuit television monitoring and offers localized chip-level repair services for enhanced reliability and convenience.

| DU104 | DU104 S | DU104 D | |

| The X-ray tube is included internally | The X-ray tube is external | ||

| Single-wall transmission | Single-wall transmission | Double-wall transmission | |

| Workpiece | |||

| Diameter Ø | ≥219mm | ≥325mm | ≤1,500mm |

| Length | ≤13,000mm | ≤20,000mm | infinite |

| Movement Detector | |||

| Circular weld seam | Workpiece rotation | Workpiece rotation | Workpiece rotation |

| Longitudinal weld seam | Workpiece movement | Workpiece movement or synchronous movement of the X-ray source and detector | Workpiece movement or synchronous movement of the X-ray source and detector |

| Stroke/Speed | |||

| Longitudinal Tx | Speed 0-15 m/min | Speed 0-15 m/min | Speed 0-15 m/min |

| Rotational Rx | 360°, Line speed 0-15 m/min | ||

| Vertical Tz axis | (Ø max/2)+ | (Ø max/2)+ | ≤1,000+mm |

| Tilted Ry | - | - | ±15° |

| Focal length | 350mm~700mm | 350mm~700mm | 350mm~18,000mm |

| X-ray source | 160kV – 600kV(See DG series X-ray source) | ||

| Imaging Detector | Digital Flat Panel | ||

| Input Window | 300mm×250mm | ||

| Pixel | 1024×1024 with a spacing of 200μm | ||

| Gray Scale Level | 65,536(16bit) | ||

| Frame Rate | 1fps – 25fps | ||

| Dynamic Range | 82dB | ||

| Control Console | 1,200mm×1,000mm×750mm, 65kg | ||

| Power Supply | 3P×380Vac or 1P×220Vac,50Hz | ||

| Optional Accessories | Line array detector, marking device, collimator | ||

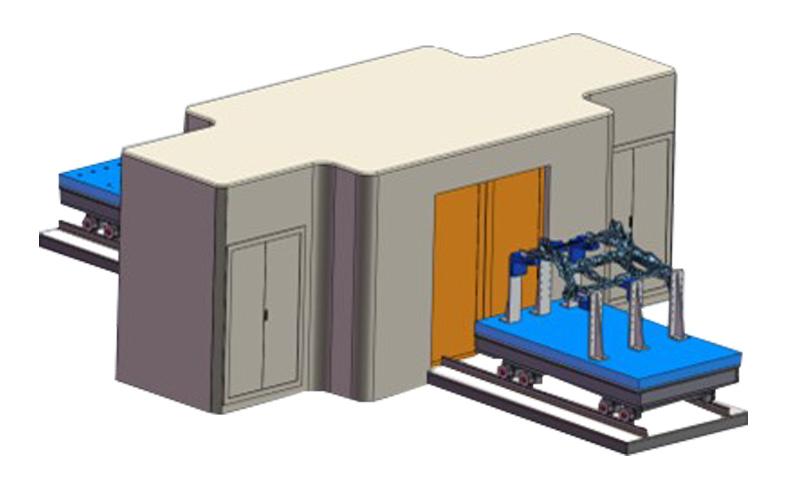

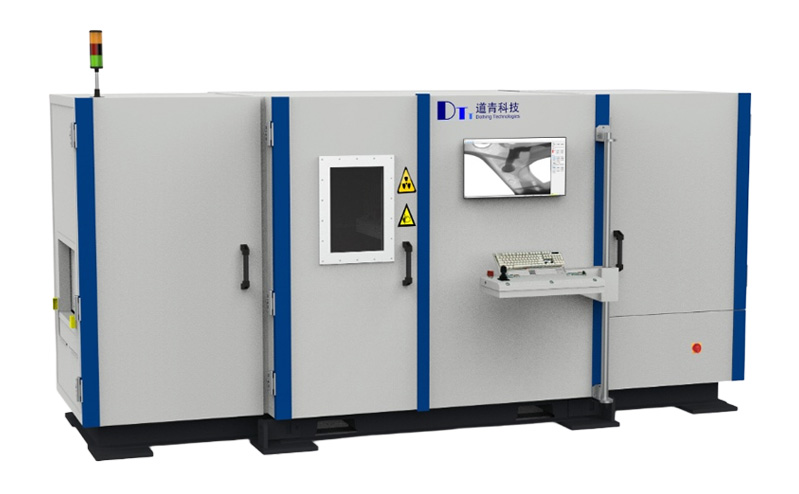

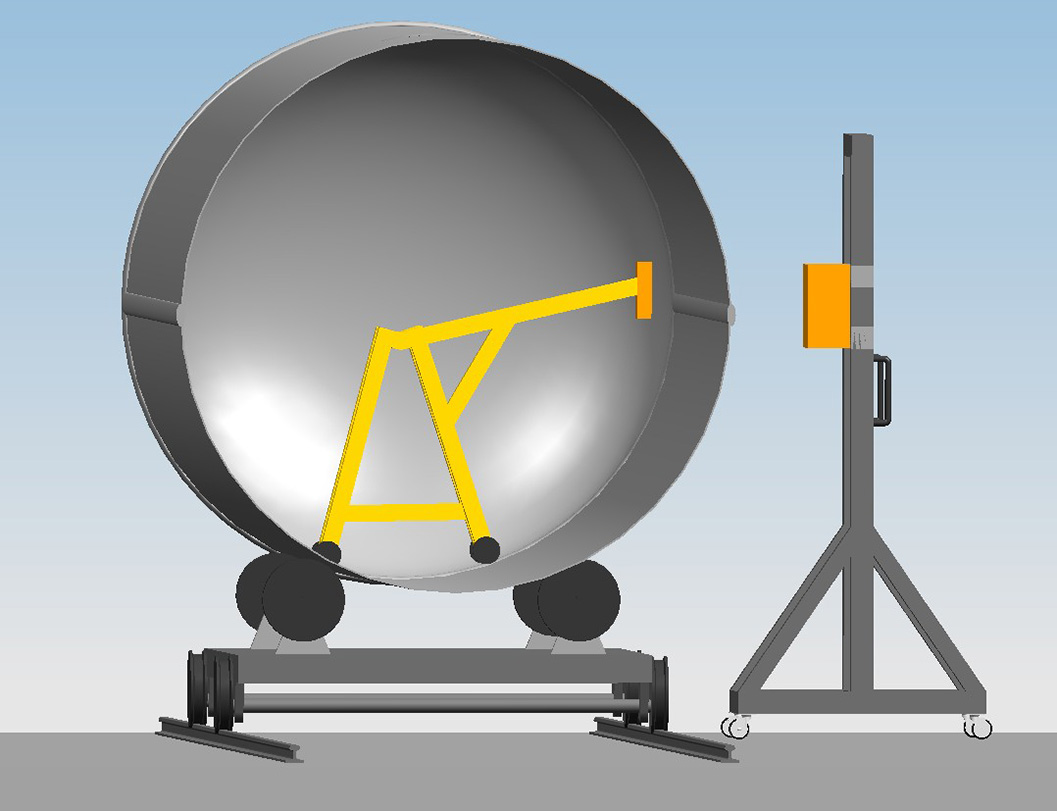

| Mechanical structure |

|

|

|

| Advantages features | · Efficient and cost-effective design · Proven and mature system layout · Expanded diameter coverage with single-wall imaging · Lower shielding costs with 6 o’clock transmission configuration | · Short high-voltage cables for enhanced reliability · Long-term operation with minimal maintenance costs · Compatible with large-diameter,long workpieces · Supports 3 o’clock or 6 o’clock irradiation configurations | · Optimized for inspecting small-diameter tanks · Axial feed design allows unlimited tank length · Suitable for tanks with end caps on both sides |

Different names for the product

Digital imaging inspection system for pressure vessel welds

X-ray inspection system for pressure vessels

Pressure Vessel Weld Digital Imaging Inspection System

Pressure Vessel X-ray Inspection System

if you cannot find answer to your question our FAQ, you can alwas contact us. web will answer you shortly!