Say Goodbye to “Destructive Spot Checks” : How X-rays Reshape the Boundaries of Quality Inspection

Dothing Information Department2025-11-2069 Views

In the past manufacturing industry, there was a paradoxical pain point: to know whether the internal quality of a batch of products was perfect, it was necessary to randomly select a few "lucky ones" to destroy it. This is the traditional destructive testing - by cutting, crushing or tearing the sample to assess its internal structure, strength or defects. This method is like "the blind men touching the elephant", not only costly but also unable to guarantee 100% quality.

The three major predicaments of destructive testing

1. High cost: Every damaged sample means a direct loss of materials and labor.

2. Sampling risk: Destructive testing is essentially a gamble. Ninety-nine products were qualified, and the 100th one that was randomly inspected was also qualified, but it cannot be guaranteed whether the 101st one has any hidden defects. This kind of trust based on probability is the bottleneck in the pursuit of high quality.

3. Information lag: Destructive tests usually take a long time. By the time the results come out, the production line may have continuously produced a large number of non-conforming products, causing huge losses from rework or scrapping.

The emergence of X-ray non-destructive testing technology has completely broken this deadlock. It is like equipping the production line with a pair of "X-ray eyes", bringing about revolutionary changes:

● No damage required, 100% inspection becomes possible: Now, every product leaving the factory can undergo a "full physical examination" of internal quality. Whether it is to detect air holes in wheel hubs, electrode alignment in batteries, or foreign objects in food, X-rays can penetrate everything inside the product without touching or damaging it. This has brought about a qualitative change from "trust sampling" to "trust each one".

● Extremely fast speed, seamless integration with production lines: Modern industrial X-ray inspection systems can complete the scanning, imaging and automatic determination of individual products within seconds or even milliseconds. This high efficiency enables it to be easily integrated into high-speed production lines, achieving online and real-time quality monitoring, truly transforming quality control from "post-event remediation" to "in-process control".

From "eliminating defective products" to "optimizing processes" : Besides screening for defects, the vast amount of data generated by X-ray inspection is even more valuable. By analyzing the types, locations and distributions of defects, engineers can precisely identify the weak links in the production process, thereby optimizing casting, welding, assembly and other processes in reverse, improving the yield of qualified products from the source and achieving continuous quality improvement.

X-ray non-destructive testing is not merely a more advanced testing tool; it represents an innovation in the philosophy of quality management. It has enabled us to bid farewell to the "guessing game" at the expense of products and enter a brand-new quality era characterized by full inspection, immediate feedback, and data-driven. In the increasingly competitive manufacturing industry, this is not only a powerful tool for pursuing "zero defects", but also a crucial link for enterprises to build core competitiveness.

Dothing Technologies

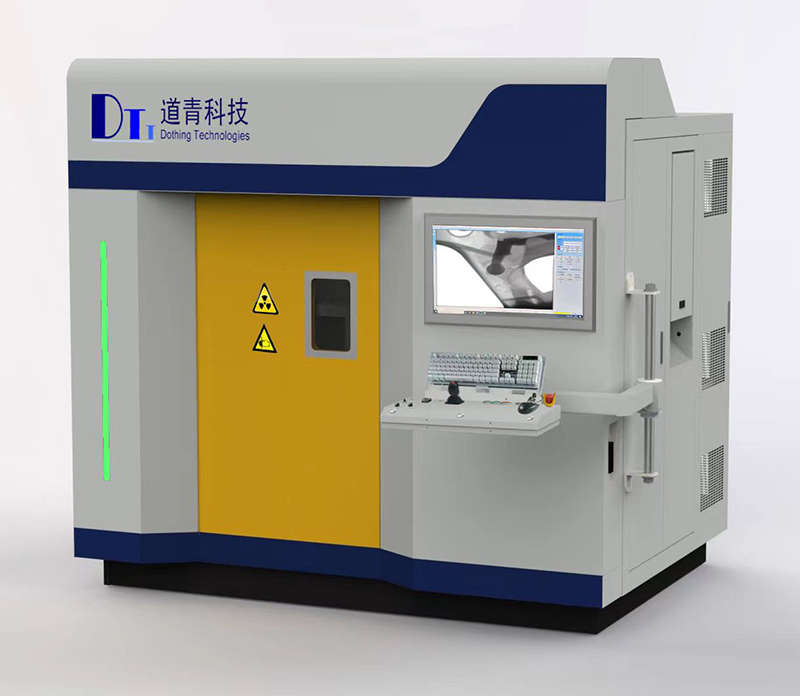

Established in September 2006,Sales, and service of advanced X-ray digital imaging, non-destructive testing equipment Cutting-edge digital X-ray inspection solutions and integrating into their systems. World-leading non-destructive testing technology and products and relying on professional service team.Search

Latest News

Our products

Integrated Large Die Casting X-ray Digital Imaging Detection System

Semi-Automatic Wheel Hub X-Ray Inspection System

Fully Automatic Wheel X-Ray Inspection System

General Semi-Automatic X-Ray Inspection System

Steel Gas Cylinders Welding Seam X-Ray Inspection System

Small-Diameter Pipeline Welding Seam X-Ray Inspection System