X-rays & Partial Discharge: Detecting What the Eye Can’t See

Dothing Information Department2025-11-13115 Views

In the fields of industrial inspection and power operation and maintenance, there are two crucial non-destructive testing technologies: X-ray inspection and partial discharge inspection. They are like a doctor with "X-ray vision" and a doctor with "sharp ears", conducting "physical examinations" on equipment and facilities in completely different ways to prevent problems before they occur.

X-ray Inspection: Seeing the "sharp eyes" Inside

What is it? X-ray detection takes advantage of the powerful penetrating ability of high-energy electromagnetic waves. Just like taking an X-ray of the human body, when the rays penetrate the inspected object, different materials and structures inside will absorb different doses of rays, thus forming a grayscale image of the internal structure on the detector.

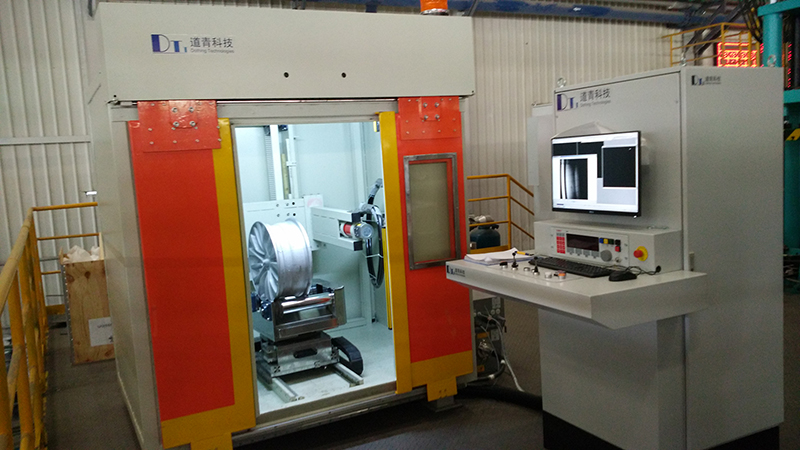

What can it do? It enables us to directly "see" the inner world that is beyond the reach of the naked eye. In industry, it is used to detect pores, cracks and inclusions inside wheel hubs, welds and castings. In the field of public security, it is the core technology of security inspection machines. In archaeology, it can reveal the internal structure and restoration traces of cultural relics. Its core value lies in providing intuitive and concrete "spatial structure" information.

X-ray inspection equipment

Partial discharge detection: The "Early Warning Sentinel" of Listening Insulation

What is it? Partial discharge detection "listens" to the weak signals inside electrical equipment. Under the effect of high voltage, the weak points in the insulation layer of equipment (such as the insulation materials inside cables and transformers) will cause tiny and repetitive breakdowns, that is, "partial discharge". This process generates high-frequency electromagnetic waves, ultrasonic waves and chemical decomposition products.

What can it do? It is like a sharp sentry, capable of early warning of potential insulation deterioration risks by capturing these faint sound, light, electrical and chemical signals in the early stage of insulation failure. It is the core means for online monitoring of the insulation status of equipment in power systems, high-voltage cables, substations, etc. Its core value lies in providing early "status trend" information to prevent the occurrence of catastrophic faults (such as power outages, fires).

Summary: A complementary golden pair

In short, X-rays are responsible for "seeing the structure", solving the problems of "what it is" and "where it is". Partial discharge, on the other hand, is responsible for "listening to the status", answering questions such as "whether it is healthy" and "what the risk is". One guards the physical integrity of the materials, while the other supervises the insulation health of the electrical equipment. Together, they form the indispensable technical foundation for the safe and reliable operation of modern industrial and power systems.

Dothing Technologies

Established in September 2006,Sales, and service of advanced X-ray digital imaging, non-destructive testing equipment Cutting-edge digital X-ray inspection solutions and integrating into their systems. World-leading non-destructive testing technology and products and relying on professional service team.Search

Latest News

Our products

Integrated Large Die Casting X-ray Digital Imaging Detection System

Semi-Automatic Wheel Hub X-Ray Inspection System

Fully Automatic Wheel X-Ray Inspection System

General Semi-Automatic X-Ray Inspection System

Steel Gas Cylinders Welding Seam X-Ray Inspection System

Small-Diameter Pipeline Welding Seam X-Ray Inspection System