The core role of X-ray flaw detection in the safety of pressure vessels and pipelines

Dothing Information Department2025-10-1845 Views

Pressure vessels and pipelines, as key equipment for transporting and storing high-risk media in industries such as energy and chemical engineering, their safety is closely related to life, property and environmental protection. X-ray flaw detection is one of the most core non-destructive testing technologies to ensure the manufacturing and in-service safety of these pressure-bearing equipment.

During the manufacturing stage, it is mainly used for comprehensive inspection of longitudinal/circumferential welds of container cylinders, fillet welds of nozzles, etc. Through X-ray images, it is possible to clearly identify whether there are dangerous defects such as incomplete fusion, incomplete penetration, cracks, and strip-shaped slag inclusions inside the weld seam. These defects, under the periodic loading of pressure and the corrosive effect of the medium, are highly likely to become the source of crack initiation and propagation, eventually leading to equipment leakage or explosion.

X-ray flaw detection is also indispensable in the in-service inspection of equipment. For pipelines that have been operating in corrosive environments for many years, the thinning of wall thickness, internal corrosion pits and stress corrosion cracks can be detected and evaluated from the outside without the need for cutting or shutdown. This provides a direct basis for predicting the remaining lifespan of equipment and formulating scientific maintenance and replacement strategies. By conducting regular X-ray "check-ups" for these "industrial arteries", the occurrence of serious accidents can be effectively prevented, achieving a leap in safety management from "post-event remediation" to "pre-event prevention", and the economic and social benefits are huge.

Dothing Technologies

Established in September 2006,Sales, and service of advanced X-ray digital imaging, non-destructive testing equipment Cutting-edge digital X-ray inspection solutions and integrating into their systems. World-leading non-destructive testing technology and products and relying on professional service team.Search

Latest News

Our products

Integrated Large Die Casting X-ray Digital Imaging Detection System

Semi-Automatic Wheel Hub X-Ray Inspection System

Fully Automatic Wheel X-Ray Inspection System

General Semi-Automatic X-Ray Inspection System

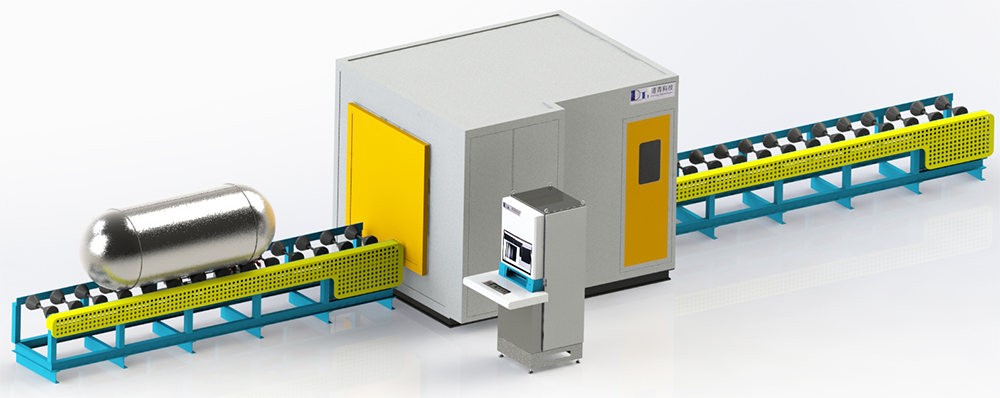

Steel Gas Cylinders Welding Seam X-Ray Inspection System

Small-Diameter Pipeline Welding Seam X-Ray Inspection System