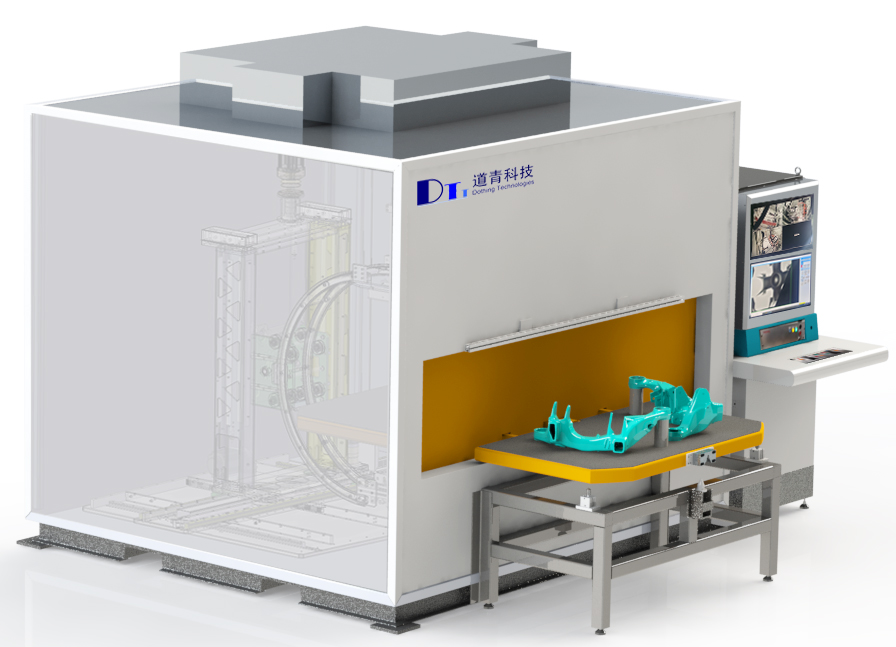

Rotary X-ray testing equipment: equipped with a “rotating CT eye” for industrial quality inspection

Dothing Information Department2025-10-1850 Views

In the field of industrial non-destructive testing, when dealing with workpieces with complex structures and irregular shapes, how to achieve internal quality inspection without blind spots and with high precision has always been a difficult problem. The emergence of rotary X-ray inspection equipment has perfectly solved this pain point. By allowing the workpiece to rotate 360°, it achieves all-round scanning from multiple angles, just like installing a pair of "rotating CT eyes" for industrial quality inspection, and is becoming a powerful tool for quality control in high-end manufacturing.

Core Advantage One: 360° No blind spots, say goodbye to detection blind zones. When traditional fixed X-ray inspection is used to deal with complex workpieces (such as wheels, engine blades, and precision castings), single-angle shooting is very likely to cause detection blind zones due to structural overlap, resulting in internal defects such as pores, cracks, and shrinkage porosity being blocked and missed. The core advantage of rotary equipment lies in its ability to drive the workpiece to perform precise 360° rotation. Combined with a radiation source and detector, it can obtain continuous projection data of the workpiece for a full cycle. This means that no matter where the defect is hidden, it can be clearly captured by the ray beam from at least one Angle, truly achieving all-round detection without blind spots and greatly enhancing the reliability and accuracy of the detection.

Core Advantage Two: Three-dimensional imaging, exposing defects in their true form. Rotary equipment is not merely about taking a few more photos. By collecting a vast amount of two-dimensional projection data of the workpiece's rotation once and applying professional CT (Computed Tomography) reconstruction algorithms, a three-dimensional model of the workpiece can be generated. The operator can freely rotate and cut this three-dimensional model on the computer, and observe the internal structure and defects of the workpiece from any Angle and level. This ability makes the location, quantitative and qualitative analysis of defects more intuitive and accurate than ever before. Whether it is assessing the direction of cracks or measuring the precise size of pores, it has become a piece of cake.

Rotary detection equipment

Core Advantage 3: Enhance efficiency and achieve automated batch inspection. Compared with the multi-angle shooting method that requires multiple manual adjustments to the workpiece's posture, the rotary inspection realizes a one-click automated process. The operator only needs to place the workpiece properly, start the program, and the equipment will automatically complete the entire process of workpiece clamping, rotation, scanning and image reconstruction. This not only significantly reduces the skill requirements and labor intensity for operators, but more importantly, it standardizes the inspection cycle, making it particularly suitable for integration into automated production lines to achieve 7* 24-hour uninterrupted efficient batch inspection. While improving quality, it also ensures production capacity.

Core Advantage Four: Strong adaptability and multi-functionality in one machine. By changing different fixtures and adjusting scanning parameters, a rotary X-ray inspection device can meet the inspection requirements of various specifications and materials of workpieces, ranging from small precision parts to medium-sized complex castings. This powerful flexibility makes it an indispensable universal high-quality inspection platform in fields such as aerospace, automotive manufacturing, precision electronics, and military industry.

In summary, the rotary X-ray inspection equipment has achieved a technological leap from "two-dimensional plane" to "three-dimensional" and from "sampling inspection" to "comprehensive physical examination" through its unique rotary scanning mode. It is not only the "sharp eyes" that detect defects, but also the core equipment that drives the manufacturing industry towards high precision, high efficiency and high reliability, providing a solid quality foundation for high-end intelligent manufacturing.

Dothing Technologies

Established in September 2006,Sales, and service of advanced X-ray digital imaging, non-destructive testing equipment Cutting-edge digital X-ray inspection solutions and integrating into their systems. World-leading non-destructive testing technology and products and relying on professional service team.Search

Latest News

Our products

Integrated Large Die Casting X-ray Digital Imaging Detection System

Semi-Automatic Wheel Hub X-Ray Inspection System

Fully Automatic Wheel X-Ray Inspection System

General Semi-Automatic X-Ray Inspection System

Steel Gas Cylinders Welding Seam X-Ray Inspection System

Small-Diameter Pipeline Welding Seam X-Ray Inspection System